A Little Porsche Paint History

#1

A Little Porsche Paint History

A high level of skilled craftsmanship and experience has always been required when painting the Porsche vehicles on account of the curvature of the body. Determined by the increases in production new premises were required over time, which led to the construction of a new building in 1969, the paint shop or building 40. In 1975, Porsche was the first manufacturer to introduce hot-dip galvanized steel for the entire body. This considerably improved corrosion protection. From 1980, painting of aluminum parts (hood, fender and doors) was added for the Porsche 928. In February 1986, a new body paint shop (in building 40A) was brought into operation with the first coating procedure in the cathodic dip tank (KTL). It was subsequently brought up to the stage in July 1986 where it was capable of handling production quantities. The old paint complex for painting plastic add-on parts was used until 1992.

The new paint shop brought a number of benefits with it:

Courtesey of Porsche AG

From 1993 to 1995 the level of automation was increased further. Robots used for sealing purposes contributed to the increase in efficiency and at the same time humanization of the work place. Environmental issues, in particular, gained in significance. From 1992, Porsche embraced water-based paint technology. Since 1997 water-based filler has been in use. In 1995, continuous solvent emission monitoring was introduced and a contract under public law regarding long-term control of maximum emission and noise levels was concluded with the city of Stuttgart.

Boxster in cathodic dip coating bath (corrosion protection)

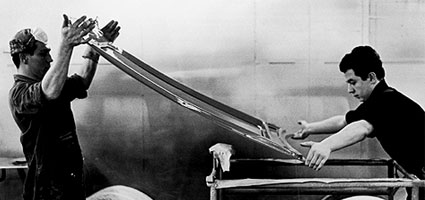

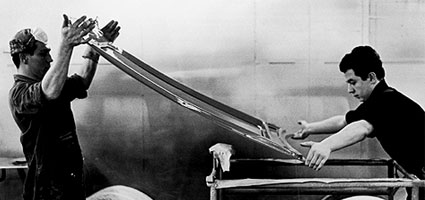

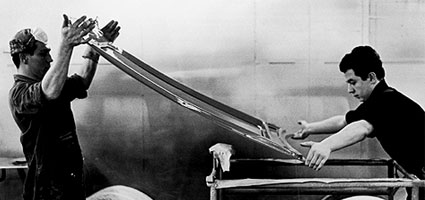

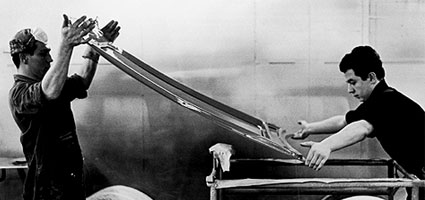

Manual application of water-base paint

Automatic clearcoat application

Manual application of water-base paint

Infrared radiators dry the water-base paint

Manual paint inspection

Courtesey of Porsche AG

I'm always amazed to learn about the technology of paint. What other product in the world takes the daily abuse, has to look good, and has to last a minimum of ten years? Automotive paint is truly a marvel on its own.

The great news is as long as paint is cared for properly, it can look great for decades. The paint quality that is on these higher-end cars now days would make the original developers of these cars proud.

The new paint shop brought a number of benefits with it:

- Improvement of corrosion protection by means of cathodic dip painting

- Restriction of the solvent emissions by means of an exhaust air decontamination system

- Use of robots for applying the underbody protection

- Increase of the potential daily number of items to 140 bodies

- Heat recovery via a countercurrent heat exchanger

Courtesey of Porsche AG

From 1993 to 1995 the level of automation was increased further. Robots used for sealing purposes contributed to the increase in efficiency and at the same time humanization of the work place. Environmental issues, in particular, gained in significance. From 1992, Porsche embraced water-based paint technology. Since 1997 water-based filler has been in use. In 1995, continuous solvent emission monitoring was introduced and a contract under public law regarding long-term control of maximum emission and noise levels was concluded with the city of Stuttgart.

Boxster in cathodic dip coating bath (corrosion protection)

Manual application of water-base paint

Automatic clearcoat application

Manual application of water-base paint

Infrared radiators dry the water-base paint

Manual paint inspection

Courtesey of Porsche AG

I'm always amazed to learn about the technology of paint. What other product in the world takes the daily abuse, has to look good, and has to last a minimum of ten years? Automotive paint is truly a marvel on its own.

The great news is as long as paint is cared for properly, it can look great for decades. The paint quality that is on these higher-end cars now days would make the original developers of these cars proud.

#4

Interesting article, thanks for shareing-

Timeline that shows the progression of automotive paint finishes -

1924 - Spray painting was introduced and the only available material was nitrocellulose lacquer.

1924 - Spray painting was introduced and the only available material was nitrocellulose lacquer.

1929 - Alkyd enamel was introduced. It was tougher than lacquer and needed no compounding. Most manufacturers used either lacquer or enamel from this point on, depending upon availability and factory conditions.

1929 - Alkyd enamel was introduced. It was tougher than lacquer and needed no compounding. Most manufacturers used either lacquer or enamel from this point on, depending upon availability and factory conditions.

1940 - Chrysler and Ford changed over to enamels exclusively. Metal flakes in paints were introduced by the aluminium industry.

1940 - Chrysler and Ford changed over to enamels exclusively. Metal flakes in paints were introduced by the aluminium industry.

1956 - Acrylic lacquer was popularized due to its better sheen and durability. GM went exclusively to the material.

1956 - Acrylic lacquer was popularized due to its better sheen and durability. GM went exclusively to the material.

1960 - Paints utilized chromates, lead and other heavy metal chemicals that produced durable finishes. Ford called its enamels "proselytized" paints.

1960 - Paints utilized chromates, lead and other heavy metal chemicals that produced durable finishes. Ford called its enamels "proselytized" paints.

1970 - The first aftermarket polyurethane enamel, Imron, was introduced by DuPont. It utilized a two-part chemical system that was extremely durable. DuPont experimented with waterborne solvents during this period.

1970 - The first aftermarket polyurethane enamel, Imron, was introduced by DuPont. It utilized a two-part chemical system that was extremely durable. DuPont experimented with waterborne solvents during this period.

1978 - High solids acrylic enamel becomes the paint choice of most manufacturers. These have the advantage of requiring fewer coats.

1978 - High solids acrylic enamel becomes the paint choice of most manufacturers. These have the advantage of requiring fewer coats.

1982 - Base/clear coat paint system adopted as automotive paint system industry standard.

1982 - Base/clear coat paint system adopted as automotive paint system industry standard.

1987 - Water-borne primers introduced. These paints are not actually dissolved in water, but use water as the medium to help transfer the paint from the can onto the car. They took a long time to perfect at the factory level, during which many durability problems were encountered.

1987 - Water-borne primers introduced. These paints are not actually dissolved in water, but use water as the medium to help transfer the paint from the can onto the car. They took a long time to perfect at the factory level, during which many durability problems were encountered.

1989 - Water-borne base coats introduced.

1989 - Water-borne base coats introduced.

1990 - Clean Air Act sets strict limits on volatile organic compounds (VOC) emitted during paint applications. Both Japanese and European car manufacturers began using metallic (polychromatic) paint that contained 100-300-nanometer mica chips in an acrylic paint with a clear coat.

1990 - Clean Air Act sets strict limits on volatile organic compounds (VOC) emitted during paint applications. Both Japanese and European car manufacturers began using metallic (polychromatic) paint that contained 100-300-nanometer mica chips in an acrylic paint with a clear coat.

1997 - Anti-chip primers become industry standard.

1997 - Anti-chip primers become industry standard.

2004- PPG Industries CeramiClear is a binary clear coat composition designed to offer long-term gloss and durability. According to PPG engineers, this is the first automotive clear coat to use nanoparticle technology. CeramiClear can still be damaged by keys but most day-to-day use including degradation from ultraviolet radiation, acid rain and salt is eliminated. Additionally, reported test results show CeramiClear holds onto more than 80 percent of its gloss appearance after several months of weathering and being run through the car wash.

2004- PPG Industries CeramiClear is a binary clear coat composition designed to offer long-term gloss and durability. According to PPG engineers, this is the first automotive clear coat to use nanoparticle technology. CeramiClear can still be damaged by keys but most day-to-day use including degradation from ultraviolet radiation, acid rain and salt is eliminated. Additionally, reported test results show CeramiClear holds onto more than 80 percent of its gloss appearance after several months of weathering and being run through the car wash.

Timeline that shows the progression of automotive paint finishes -

An extract from one of a series of in-depth detailing articles © TOGWT ™ Ltd Copyright 2002-2008, all rights reserved.

#5

Interesting article, thanks for shareing-

Timeline that shows the progression of automotive paint finishes -

1924 - Spray painting was introduced and the only available material was nitrocellulose lacquer.

1924 - Spray painting was introduced and the only available material was nitrocellulose lacquer.

1929 - Alkyd enamel was introduced. It was tougher than lacquer and needed no compounding. Most manufacturers used either lacquer or enamel from this point on, depending upon availability and factory conditions.

1929 - Alkyd enamel was introduced. It was tougher than lacquer and needed no compounding. Most manufacturers used either lacquer or enamel from this point on, depending upon availability and factory conditions.

1940 - Chrysler and Ford changed over to enamels exclusively. Metal flakes in paints were introduced by the aluminium industry.

1940 - Chrysler and Ford changed over to enamels exclusively. Metal flakes in paints were introduced by the aluminium industry.

1956 - Acrylic lacquer was popularized due to its better sheen and durability. GM went exclusively to the material.

1956 - Acrylic lacquer was popularized due to its better sheen and durability. GM went exclusively to the material.

1960 - Paints utilized chromates, lead and other heavy metal chemicals that produced durable finishes. Ford called its enamels "proselytized" paints.

1960 - Paints utilized chromates, lead and other heavy metal chemicals that produced durable finishes. Ford called its enamels "proselytized" paints.

1970 - The first aftermarket polyurethane enamel, Imron, was introduced by DuPont. It utilized a two-part chemical system that was extremely durable. DuPont experimented with waterborne solvents during this period.

1970 - The first aftermarket polyurethane enamel, Imron, was introduced by DuPont. It utilized a two-part chemical system that was extremely durable. DuPont experimented with waterborne solvents during this period.

1978 - High solids acrylic enamel becomes the paint choice of most manufacturers. These have the advantage of requiring fewer coats.

1978 - High solids acrylic enamel becomes the paint choice of most manufacturers. These have the advantage of requiring fewer coats.

1982 - Base/clear coat paint system adopted as automotive paint system industry standard.

1982 - Base/clear coat paint system adopted as automotive paint system industry standard.

1987 - Water-borne primers introduced. These paints are not actually dissolved in water, but use water as the medium to help transfer the paint from the can onto the car. They took a long time to perfect at the factory level, during which many durability problems were encountered.

1987 - Water-borne primers introduced. These paints are not actually dissolved in water, but use water as the medium to help transfer the paint from the can onto the car. They took a long time to perfect at the factory level, during which many durability problems were encountered.

1989 - Water-borne base coats introduced.

1989 - Water-borne base coats introduced.

1990 - Clean Air Act sets strict limits on volatile organic compounds (VOC) emitted during paint applications. Both Japanese and European car manufacturers began using metallic (polychromatic) paint that contained 100-300-nanometer mica chips in an acrylic paint with a clear coat.

1990 - Clean Air Act sets strict limits on volatile organic compounds (VOC) emitted during paint applications. Both Japanese and European car manufacturers began using metallic (polychromatic) paint that contained 100-300-nanometer mica chips in an acrylic paint with a clear coat.

1997 - Anti-chip primers become industry standard.

1997 - Anti-chip primers become industry standard.

2004- PPG Industries CeramiClear is a binary clear coat composition designed to offer long-term gloss and durability. According to PPG engineers, this is the first automotive clear coat to use nanoparticle technology. CeramiClear can still be damaged by keys but most day-to-day use including degradation from ultraviolet radiation, acid rain and salt is eliminated. Additionally, reported test results show CeramiClear holds onto more than 80 percent of its gloss appearance after several months of weathering and being run through the car wash.

2004- PPG Industries CeramiClear is a binary clear coat composition designed to offer long-term gloss and durability. According to PPG engineers, this is the first automotive clear coat to use nanoparticle technology. CeramiClear can still be damaged by keys but most day-to-day use including degradation from ultraviolet radiation, acid rain and salt is eliminated. Additionally, reported test results show CeramiClear holds onto more than 80 percent of its gloss appearance after several months of weathering and being run through the car wash.

Timeline that shows the progression of automotive paint finishes -

An extract from one of a series of in-depth detailing articles © TOGWT ™ Ltd Copyright 2002-2008, all rights reserved.

#6

]2004-[/FONT][/COLOR][/B] PPG Industries CeramiClear is a binary clear coat composition designed to offer long-term gloss and durability. According to PPG engineers, this is the first automotive clear coat to use nanoparticle technology. CeramiClear can still be damaged by keys but most day-to-day use including degradation from ultraviolet radiation, acid rain and salt is eliminated. Additionally, reported test results show CeramiClear holds onto more than 80 percent of its gloss appearance after several months of weathering and being run through the car wash.

Haha, we all know that CeramiClear isn't half as good as they claim. If you look at a new black c040 Benz, and squint your eyes, the thing scratches.

John

An extract from one of a series of in-depth detailing articles © TOGWT ™ Ltd Copyright 2002-2008, all rights reserved.

[/QUOTE]Haha, we all know that CeramiClear isn't half as good as they claim. If you look at a new black c040 Benz, and squint your eyes, the thing scratches.

John

#7

Very interesting stuff!

I remember watching something on one of the HD channels about the making of the Corvette C6's and they showed the special paint process that the C6's go through. Pretty amazing technology!

Thanks for sharing!

D!

I remember watching something on one of the HD channels about the making of the Corvette C6's and they showed the special paint process that the C6's go through. Pretty amazing technology!

Thanks for sharing!

D!

Trending Topics

#8

That was Ultimate Factories. They did one on Ferrari and BMW as well. Got all three on DVR. Really cool thing to watch.

#9

D!

#10

Great post Moe! I love the pic of the guy painting the door with the mask on top of his head. "Masks, we don't need no stinking masks". He probably had kids with 12 fingers and toes. It's very interesting to see that the base-coat is still manually applied.

Matt

Matt

#11

[Haha, we all know that CeramiClear isn't half as good as they claim. If you look at a new black c040 Benz, and squint your eyes, the thing scratches] John

They only claim scratch resistant (as opposed to 'will not scratch) not scratchproof

[Hard and soft are both relative terms; you can scratch the hard surface of a vehicles paint with a soft towel by the application of enough pressure. Both pressure and mechanical stress are defined as force per unit area. These two forces are the subject of Newton's third law of motion; the law of reciprocal actions [: to every action there is an equal and opposite reaction

How can a hard clear coat be so easily scratched? A force acts through a body that has a surface area; if the surface area is really small while maintaining an equal force, the pressure becomes astronomical and the object under pressure capable of penetrating the surface of an otherwise tough material. That’s why a micro fine thread that is twice as fine as silk and a 100 times finer than a human hair, in an otherwise soft towel will scratch your paint. And the same reason a mosquito can penetrate a rhino hide with its proboscis (stinger).] TOGWT

They only claim scratch resistant (as opposed to 'will not scratch) not scratchproof

[Hard and soft are both relative terms; you can scratch the hard surface of a vehicles paint with a soft towel by the application of enough pressure. Both pressure and mechanical stress are defined as force per unit area. These two forces are the subject of Newton's third law of motion; the law of reciprocal actions [: to every action there is an equal and opposite reaction

How can a hard clear coat be so easily scratched? A force acts through a body that has a surface area; if the surface area is really small while maintaining an equal force, the pressure becomes astronomical and the object under pressure capable of penetrating the surface of an otherwise tough material. That’s why a micro fine thread that is twice as fine as silk and a 100 times finer than a human hair, in an otherwise soft towel will scratch your paint. And the same reason a mosquito can penetrate a rhino hide with its proboscis (stinger).] TOGWT

Last edited by TOGWT; 05-15-2009 at 03:49 AM.

#12

Paint

A high level of skilled craftsmanship and experience has always been required when painting the Porsche vehicles on account of the curvature of the body. Determined by the increases in production new premises were required over time, which led to the construction of a new building in 1969, the paint shop or building 40. In 1975, Porsche was the first manufacturer to introduce hot-dip galvanized steel for the entire body. This considerably improved corrosion protection. From 1980, painting of aluminum parts (hood, fender and doors) was added for the Porsche 928. In February 1986, a new body paint shop (in building 40A) was brought into operation with the first coating procedure in the cathodic dip tank (KTL). It was subsequently brought up to the stage in July 1986 where it was capable of handling production quantities. The old paint complex for painting plastic add-on parts was used until 1992.

The new paint shop brought a number of benefits with it:

Courtesey of Porsche AG

From 1993 to 1995 the level of automation was increased further. Robots used for sealing purposes contributed to the increase in efficiency and at the same time humanization of the work place. Environmental issues, in particular, gained in significance. From 1992, Porsche embraced water-based paint technology. Since 1997 water-based filler has been in use. In 1995, continuous solvent emission monitoring was introduced and a contract under public law regarding long-term control of maximum emission and noise levels was concluded with the city of Stuttgart.

Boxster in cathodic dip coating bath (corrosion protection)

Manual application of water-base paint

Automatic clearcoat application

Manual application of water-base paint

Infrared radiators dry the water-base paint

Manual paint inspection

Courtesey of Porsche AG

I'm always amazed to learn about the technology of paint. What other product in the world takes the daily abuse, has to look good, and has to last a minimum of ten years? Automotive paint is truly a marvel on its own.

The great news is as long as paint is cared for properly, it can look great for decades. The paint quality that is on these higher-end cars now days would make the original developers of these cars proud.

The new paint shop brought a number of benefits with it:

- Improvement of corrosion protection by means of cathodic dip painting

- Restriction of the solvent emissions by means of an exhaust air decontamination system

- Use of robots for applying the underbody protection

- Increase of the potential daily number of items to 140 bodies

- Heat recovery via a countercurrent heat exchanger

Courtesey of Porsche AG

From 1993 to 1995 the level of automation was increased further. Robots used for sealing purposes contributed to the increase in efficiency and at the same time humanization of the work place. Environmental issues, in particular, gained in significance. From 1992, Porsche embraced water-based paint technology. Since 1997 water-based filler has been in use. In 1995, continuous solvent emission monitoring was introduced and a contract under public law regarding long-term control of maximum emission and noise levels was concluded with the city of Stuttgart.

Boxster in cathodic dip coating bath (corrosion protection)

Manual application of water-base paint

Automatic clearcoat application

Manual application of water-base paint

Infrared radiators dry the water-base paint

Manual paint inspection

Courtesey of Porsche AG

I'm always amazed to learn about the technology of paint. What other product in the world takes the daily abuse, has to look good, and has to last a minimum of ten years? Automotive paint is truly a marvel on its own.

The great news is as long as paint is cared for properly, it can look great for decades. The paint quality that is on these higher-end cars now days would make the original developers of these cars proud.

Last edited by Pamgroove; 11-26-2020 at 07:01 AM. Reason: Reposted

#13

Repaint quality process

Hello and thank you for the history. My Boxster needs to be repainted and I'm concerned about quality of finish when completed compared to factory finish. Do you know what the difference is between a Porsche certified repair facility repaint and a non Porsche certified repaint?

Thank you,

Pam

Thank you,

Pam

#14

Hello and thank you for the history. My Boxster needs to be repainted and I'm concerned about quality of finish when completed compared to factory finish. Do you know what the difference is between a Porsche certified repair facility repaint and a non Porsche certified repaint?

Thank you,

Pam

Thank you,

Pam

Just make sure they have lots of Porsche experience

You'd want a Porsche Certified Repair Facility if there structural damage

Thread

Thread Starter

Forum

Replies

Last Post

Gotgolf52

Detailing

3

09-03-2013 03:35 AM