Aftermarket Wheel Quality & Safety

#1

Aftermarket Wheel Quality & Safety

There are soooo many wheels available on the aftermarket & I'm sure most are not actually being manufactured by the company whose name is on the wheel. What do I ask the wheel sellers for to prove enough engineering has gone into the design to assure it can handle the tremendous stresses they have to handle? It is easy to machine out a lot of stock to make a light wheel or to design a great looking wheel. Are there any standards wheels have to meet before they can be sold to us? I feel very comfortable with companies like HRE & BBS but what about a lot of the others I see pushing there products on 6speed. I understand Germany has something called TUV where companies have to prove there products meet certain requirements but what about in the United Sates, Italy, etc.? Very interested to hear what some of the wheel manufacturers/sellers have to say. I ask this because I had Dymags on my '08 Turbo (gone) and some people with these had problems with the centers cracking under force. The company replaced mine with a new set (even though I had no problems) that had a different alloy used for the centers.

#2

Here is a post I made in a different thread regarding some things to consider when purchasing a wheel.

Feel free to contact me directly if you had any additional questions, LonM@hrewheels.com

http://www.m3post.com/forums/showthr...1#post11598691

Feel free to contact me directly if you had any additional questions, LonM@hrewheels.com

http://www.m3post.com/forums/showthr...1#post11598691

We’ve been alerted that HRE is being dragged into this thread. While we don’t want to be anywhere near this, unfortunately our name is getting tossed around so we are forced to clarify some of the statements being made.

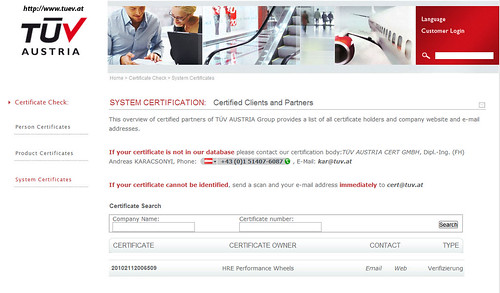

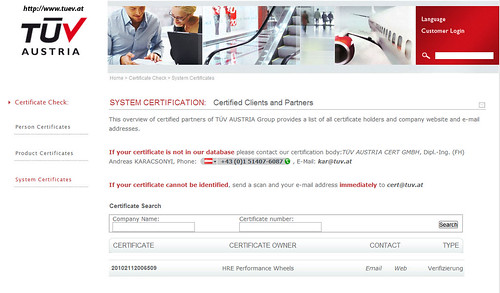

Feel free to verify our TUV certification here, http://www.tuev.at/start/browse/Webs...rter%20Partner

- Quality: Please do not equate the use of similar suppliers with similar quality. HRE does our design/engineering/CNC machining/finish/assembly here in Vista (San Diego, CA) at our OWN facility with our OWN quality management process that is TUV certified. We’re not just talking about wheels being certified. Our QUALITY MANGEMENT SYSTEM is TUV certified.

- Engineering: Our president has a B.S. from Harvey Mudd College in Engineering and an M.S from UCLA in Mechanical Engineering and came to us in 1999 after 8 years of working at Northrop Grumman’s B-2 Division doing structural analysis on aircraft. The fact that HRE has a mechanical engineer in such a lead position should make it clear we’re not just a “draw and cut” company and how proper engineering is viewed here. As for FEA we know it is way too easy to get a very “accurate INCORRECT answer”. If you have no idea what you’re doing, you’re going to end up with false confidence leading to problems. Junk in. Junk out.

Feel free to verify our TUV certification here, http://www.tuev.at/start/browse/Webs...rter%20Partner

Last edited by HRE_Wheels; 04-25-2012 at 07:59 PM.

#3

__________________

damon@tirerack.com

877-522-8473 ext. 4643

574-287-2345 ext. 4643

**Don't forget to add my name to online orders!**

Or use this link:

http://www.tirerack.com/a.jsp?a=BH1&url=index.jsp

damon@tirerack.com

877-522-8473 ext. 4643

574-287-2345 ext. 4643

**Don't forget to add my name to online orders!**

Or use this link:

http://www.tirerack.com/a.jsp?a=BH1&url=index.jsp

#4

I had OZ Racing Alleggerita HLT 18" on my GTI.

Were very light and beautiful, and very strong. Made to order in Italy. To import these wheels to Germany or Swirzerland they have to pass TÜV.

Basically, in my opinion, you can go with any known brand (HRE, OZ, BBS, etc) and not worry about quality. All you have to worry about is the choice and your wallet.

Were very light and beautiful, and very strong. Made to order in Italy. To import these wheels to Germany or Swirzerland they have to pass TÜV.

Basically, in my opinion, you can go with any known brand (HRE, OZ, BBS, etc) and not worry about quality. All you have to worry about is the choice and your wallet.

#5

#7

Carlos - lead engineer at MORR competition wheels posted a series of article surrounding wheel manufacturing, processes and certifications. Here is his article on wheel certification. If you need help in guiding you through the maze that is the wheel industry, we will gladly help in your selection.

One of the most controversial areas of wheel manufacturing is the manufacturer testing policies or testing guidelines. In this article we’ll cover the major worldwide testing standards, procedures, requirements, specifications, cost and certifications. Whether testing and certification is important I’ll leave it up to you to draw that conclusion after reading this article. Source of this information is my direct experience of nearly a decade in the automotive industry, information directly from the testing council’s official websites, Official documents, Press releases, Wikipedia and other sources.

There are the major test standards:

Background:

JWL is the quality testing standard for Japan. The Japan Light Alloy Wheel (JWL) standard is a set of performance requirements for alloy wheels overseen by the Japan Light Allow Wheel Testing Council (JWTC) in Japan. This set of standards is required for all wheels in Japan and is set by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) of this country. This ministry is part of the Japanese government and it’s responsible for the majority of Japanese laws and orders, only second to the department of defense. This standard was developed by the Japanese government to ensure the safety of automobile alloy wheels and truck. JWL Testing and certification is mandatory in Japan.

Japan Light Allow Wheel Testing Council is a cooperation between the MLIT , Japan Aluminum Association (JAA), Nippon Auto Parts Aftermarket Committee (JAWA) and Japan Vehicle Inspection Association (VIA).

Testing Requirements:

The JWL testing standards require the following tests to be performed on all passenger alloy wheels:

- Dynamic Cornering Fatigue Test

- Dynamic Radial Fatigue Test

- Impact Test

Certification and Marks:

The JWL is a self-certified test by the wheel manufacturer. Manufacturers register and certify their testing equipment with the JWTC and are then able to certify their own wheels to JWL standards and cast or forge the JWL mark onto the wheel. Once this is done the wheel is considered JWL Certified.

VIA has established a set of parameter to independently test and register the wheels to JWL or JWL-T standards. Only once VIA has tested and certified the wheels to JWL standards it can bear the VIA mark as well as the JWL mark and it’s then considered JWL Certified and VIA Registered.

It is very important to distinguish the difference between the two.

Cost:

Total cost to conduct a JWL testing and VIA certification is approximately ¥;99,650 Yen or $1,295.00 US Dollars per style and can be done simultaneously to a range of PCD or offsets. It requires approx. 3 – 4 samples wheels.

Background:

TUV (Technischer Überwachungs-Verein) is the quality testing standard for Germany. It translates to Technical Inspection Association. Every german-registered vehicle must have a certificate from TUV in order to be operated in public roads.

Testing Requirements:

The TUV testing standards require the following tests to be performed on all passenger alloy wheels:

- Dynamic Cornering Fatigue Test – Short

200,000 Cycles at 75% Max Load.

- Dynamic Cornering Fatigue Test – Long

1,800,000 Cycles at 50% Max Load.

- Dynamic Radial Fatigue Test

2000km at 2.5 Wheel Load.

- Impact Test at Valve Hole

- Impact Test in between Spokes.

- Alternating Corrosion Test

- Corrosion Test

- Material Testing

- Mounting Test

Certification and Marks:

Once a wheel has been tested and approved by the TUV, a TUV certificate is issued and a black/color copy can be included with every wheel purchase. The TUV logo can be display in the product literature, product packaging and company website.

TUV verification cannot be confused with TUV certification. TUV verification implies that the company follows a set of quality/manufacturing guidelines approved and certified by TUV. TUV certification means that a wheel has been independently tested and certified to a set of performance standards set forth by TUV.

Cost:

Total cost to conduct a TUV testing and certification is approximately €4,950 Euro or $6,800.00 US Dollars per style, per fitment, per vehicle. This fee excludes a KBA approval charge of US$750 and a Application Test Report fee of US$500. It requires over 10 sample wheels.

The manufacturer and every facility where work to the wheel is done must be ISO: 9001 certified. Cost to obtain ISO accreditation is in excess of $10,000 US Dollars per facility and must be done on a yearly basis.

SAE stands for Society of Automotive Engineers. From the SEMA website: A few years ago, SEMA and its Wheel & Tire Council (WTC) worked with the Society of Automotive Engineers (SAE) to develop an industry testing practice for aftermarket wheels. SAE J2530 (Aftermarket Wheels Performance Requirements and Testing Procedures) outlines performance and sampling guidelines, testing procedures and marking requirements for aftermarket wheels used on cars, light trucks and multipurpose vehicles. The document identifies three main areas of testing, including cornering and radial fatigue and impact strength. A manufacturer can purchase the J2530 specifications from SAE and test at its own internal lab or at any testing facility of its choosing, so long as that facility maintains the necessary equipment to perform the tests.

Testing Requirements:

The SAE testing standards require the following tests to be performed on all passenger alloy wheels, based on a Sample size of 2:

- Dynamic Cornering Fatigue Test

475,000 Cycles @ 1.35 Factor load

- Dynamic Radial Fatigue Test

1,850,000 Cycles @ 2.0 Factor Load

- Impact Test at 13°

Certification and Marks:

Wheels that conform to the SAE J2530 Standard must be marked with:

- Wheel Manufacturer’s name

- Date of Manufacture

- Part number

- Country of Manufacture

- Rim Size

- Wheel load Rating

- DOT Symbol

- SAE J2530 must be casted in, stamped on or label on wheels that conform to this standard.

Cost:

Total cost to conduct a SAE J2530 certification is approximately $1,295.00 US Dollars per style, per fitment. It requires approx. 5 samples wheels.

Article 3

One of the most controversial areas of wheel manufacturing is the manufacturer testing policies or testing guidelines. In this article we’ll cover the major worldwide testing standards, procedures, requirements, specifications, cost and certifications. Whether testing and certification is important I’ll leave it up to you to draw that conclusion after reading this article. Source of this information is my direct experience of nearly a decade in the automotive industry, information directly from the testing council’s official websites, Official documents, Press releases, Wikipedia and other sources.

Testing and Certification

There are the major test standards:

JWL

Background:

JWL is the quality testing standard for Japan. The Japan Light Alloy Wheel (JWL) standard is a set of performance requirements for alloy wheels overseen by the Japan Light Allow Wheel Testing Council (JWTC) in Japan. This set of standards is required for all wheels in Japan and is set by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) of this country. This ministry is part of the Japanese government and it’s responsible for the majority of Japanese laws and orders, only second to the department of defense. This standard was developed by the Japanese government to ensure the safety of automobile alloy wheels and truck. JWL Testing and certification is mandatory in Japan.

Japan Light Allow Wheel Testing Council is a cooperation between the MLIT , Japan Aluminum Association (JAA), Nippon Auto Parts Aftermarket Committee (JAWA) and Japan Vehicle Inspection Association (VIA).

Testing Requirements:

The JWL testing standards require the following tests to be performed on all passenger alloy wheels:

- Dynamic Cornering Fatigue Test

- Dynamic Radial Fatigue Test

- Impact Test

Certification and Marks:

The JWL is a self-certified test by the wheel manufacturer. Manufacturers register and certify their testing equipment with the JWTC and are then able to certify their own wheels to JWL standards and cast or forge the JWL mark onto the wheel. Once this is done the wheel is considered JWL Certified.

VIA has established a set of parameter to independently test and register the wheels to JWL or JWL-T standards. Only once VIA has tested and certified the wheels to JWL standards it can bear the VIA mark as well as the JWL mark and it’s then considered JWL Certified and VIA Registered.

It is very important to distinguish the difference between the two.

Cost:

Total cost to conduct a JWL testing and VIA certification is approximately ¥;99,650 Yen or $1,295.00 US Dollars per style and can be done simultaneously to a range of PCD or offsets. It requires approx. 3 – 4 samples wheels.

TUV

Background:

TUV (Technischer Überwachungs-Verein) is the quality testing standard for Germany. It translates to Technical Inspection Association. Every german-registered vehicle must have a certificate from TUV in order to be operated in public roads.

Testing Requirements:

The TUV testing standards require the following tests to be performed on all passenger alloy wheels:

- Dynamic Cornering Fatigue Test – Short

200,000 Cycles at 75% Max Load.

- Dynamic Cornering Fatigue Test – Long

1,800,000 Cycles at 50% Max Load.

- Dynamic Radial Fatigue Test

2000km at 2.5 Wheel Load.

- Impact Test at Valve Hole

- Impact Test in between Spokes.

- Alternating Corrosion Test

- Corrosion Test

- Material Testing

- Mounting Test

Certification and Marks:

Once a wheel has been tested and approved by the TUV, a TUV certificate is issued and a black/color copy can be included with every wheel purchase. The TUV logo can be display in the product literature, product packaging and company website.

TUV verification cannot be confused with TUV certification. TUV verification implies that the company follows a set of quality/manufacturing guidelines approved and certified by TUV. TUV certification means that a wheel has been independently tested and certified to a set of performance standards set forth by TUV.

Cost:

Total cost to conduct a TUV testing and certification is approximately €4,950 Euro or $6,800.00 US Dollars per style, per fitment, per vehicle. This fee excludes a KBA approval charge of US$750 and a Application Test Report fee of US$500. It requires over 10 sample wheels.

The manufacturer and every facility where work to the wheel is done must be ISO: 9001 certified. Cost to obtain ISO accreditation is in excess of $10,000 US Dollars per facility and must be done on a yearly basis.

SAE

SAE stands for Society of Automotive Engineers. From the SEMA website: A few years ago, SEMA and its Wheel & Tire Council (WTC) worked with the Society of Automotive Engineers (SAE) to develop an industry testing practice for aftermarket wheels. SAE J2530 (Aftermarket Wheels Performance Requirements and Testing Procedures) outlines performance and sampling guidelines, testing procedures and marking requirements for aftermarket wheels used on cars, light trucks and multipurpose vehicles. The document identifies three main areas of testing, including cornering and radial fatigue and impact strength. A manufacturer can purchase the J2530 specifications from SAE and test at its own internal lab or at any testing facility of its choosing, so long as that facility maintains the necessary equipment to perform the tests.

Testing Requirements:

The SAE testing standards require the following tests to be performed on all passenger alloy wheels, based on a Sample size of 2:

- Dynamic Cornering Fatigue Test

475,000 Cycles @ 1.35 Factor load

- Dynamic Radial Fatigue Test

1,850,000 Cycles @ 2.0 Factor Load

- Impact Test at 13°

Certification and Marks:

Wheels that conform to the SAE J2530 Standard must be marked with:

- Wheel Manufacturer’s name

- Date of Manufacture

- Part number

- Country of Manufacture

- Rim Size

- Wheel load Rating

- DOT Symbol

- SAE J2530 must be casted in, stamped on or label on wheels that conform to this standard.

Cost:

Total cost to conduct a SAE J2530 certification is approximately $1,295.00 US Dollars per style, per fitment. It requires approx. 5 samples wheels.

There are soooo many wheels available on the aftermarket & I'm sure most are not actually being manufactured by the company whose name is on the wheel. What do I ask the wheel sellers for to prove enough engineering has gone into the design to assure it can handle the tremendous stresses they have to handle? It is easy to machine out a lot of stock to make a light wheel or to design a great looking wheel. Are there any standards wheels have to meet before they can be sold to us? I feel very comfortable with companies like HRE & BBS but what about a lot of the others I see pushing there products on 6speed. I understand Germany has something called TUV where companies have to prove there products meet certain requirements but what about in the United Sates, Italy, etc.? Very interested to hear what some of the wheel manufacturers/sellers have to say. I ask this because I had Dymags on my '08 Turbo (gone) and some people with these had problems with the centers cracking under force. The company replaced mine with a new set (even though I had no problems) that had a different alloy used for the centers.

Thread

Thread Starter

Forum

Replies

Last Post

PenguiN

Automotive Parts & Accessories For Sale/Wanted

9

04-22-2021 07:33 PM

ModBargains

Tesla Motors Vendor Classifieds

0

08-20-2015 12:28 PM

oddjob142

Automotive Parts & Accessories For Sale/Wanted

0

08-19-2015 12:27 PM

buy, cayenne, certificate, certifioed, dott, j2530, jwl, manufactureres, mark, porsche, purchase, rims, sae, stamp, wheel