Replacing Trailing Arm Bushings on Project BMW E46

BMW rear trailing arm bushings have an important, and complicated job. If they fail on your car, it’s bad news for you.

Welcome, one and all, to 6SpeedOnline‘s project car build. This is the weekly segment where your Editor-in-Chief (that’s me) regales you all with tales of woe and misfortune of the project car variety. This time around it’s a $1,500 BMW E46 which I have been building up as a weekend warrior drift car.

Of course, a 19-year-old, $1,500 car is going to need some work, especially if track time is the end result. So, in this episode, we are talking suspension bushings. Astute readers, of which I assume the majority of you are, will be shaking your computer screens virulently, screaming “Jake, you idiot, you talked about bushings last week! Are you gypping us on our sweet, sweet content?” Of course not. Last week, I tackled subframe and differential bushings. While I have the whole car taken apart, it makes sense to replace and upgrade as many things as possible. So, this week I am replacing rear trailing arm bushings.

What are rear trailing arm bushings?

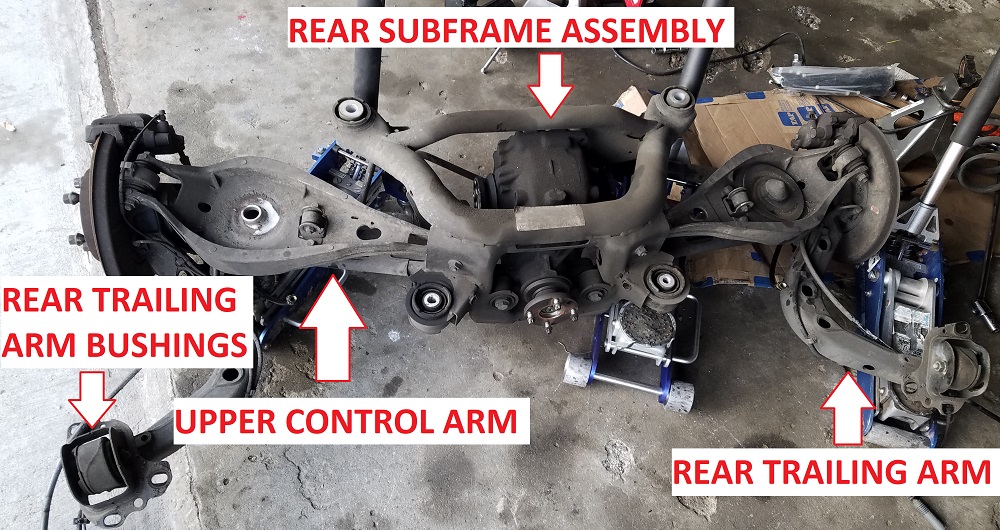

Glad you asked. The BMW E46, like many BMW models, uses a multi-link rear suspension. As the name implies, it is a fully-independent suspension with multiple suspension links that allow the rear wheels and suspension to articulate. There is an upper and lower control arm, which attach the wheel hub to the rear subframe assembly. The upper arm holds the rear suspension springs. The lower arm is utilized to adjust the rear alignment and limit unwanted suspension movement. Then there is the trailing arm, which is a massive arm that mounts the hub to the chassis of the vehicle, in front of the rear wheels.

Pictured is the complete rear suspension and subframe assembly when I pulled it out of the car. Our target this time are the rear trailing arm bushings, labelled above. I previously replaced the subframe and differential bushings with stiff polyurethane. So, you would think that the trend would continue with the “RTABs,” but you would be wrong. To explain why, it’s time to talk about how RTABs work.

How do rear trailing arm bushings work?

There are several different kinds of suspension bushings, and they all have different jobs.

Some bushings are supposed to keep things in place, and, ideally, not move at all. Those would be, for example, subframe bushings. They locate the subframe to the chassis, that’s it. There should be no movement here. So, there suspension bushings can be designed as stiffly as possible, to minimize deflection, or movement.

Some bushings are meant to move. Control arm bushings, for example, mount the control arms to the suspension knuckle. The control arm has to move up, and down as the suspension compresses and rebounds. The control arm has a single-axis movement, up, or down. If there is much side-to-side movement, there is a problem. Since there is movement here, a polyurethane or rubber bushing can be used here. Ideally, the bushing will be firm enough to minimize deflection, and side-to-side movement, but not have any binding. The suspension should be able to freely move up and down on that single axis. Again, pretty simple.

Then, there are some bushings that are meant to move, but in multiple directions. These are called multi-axis bushings. The rear trailing arms utilize a multi-axis bushing. Due the position of the trailing arm, and its design, the arm has to be able to articulate up and down, and from side-to-side at the same time. It’s a complex, yet brilliant piece of design. As the suspension compresses, the control arms move up, meanwhile, the trailing arm is moving up and angling inwards, at the same time. The reverse is true as the suspension rebounds, the control arms move downwards, while the trailing arm moves downwards, while tilting outwards, at the same time.