Behind the Scenes: FDM and the Future of Carbon

#1

Behind the Scenes: FDM and the Future of Carbon

As part of our "open door policy" here at Champion, we love giving our customers, potential customers, and fans an inside look at the daily operations of our company and how our parts are made. The newest addition to our Werks1 manufacturing facility is our new Stratasys Fused Deposition Modeling machine. Essentially, the FDM takes a 3 dimensional CAD design and allows us to print a mold front that design. Print? Watch the video and you'll see exactly what that means. The result of the printing process is a mold that is made of a special soluble support material. That mold can then be wrapped 360º in carbon, eliminating the need for any seams in the finished part. Once wrapped, the completed part is submerged in a special solution that dissolves the soluble support, leaving only the finished carbon piece. The other great thing about the FDM process is that changes can be made to the mold of a given part at any time, on the computer, without the need for producing a new mold every time a change is made.

Stay tuned for some more information about some pretty awesome new parts for the 997TT that are coming soon. Meanwhile, check out the video below showing the FDM printing the molds for our revised 997 Turbo carbon fiber inlet pipes. Enjoy

http://www.youtube.com/watch?v=wLAJ5sdtV6c

Stay tuned for some more information about some pretty awesome new parts for the 997TT that are coming soon. Meanwhile, check out the video below showing the FDM printing the molds for our revised 997 Turbo carbon fiber inlet pipes. Enjoy

http://www.youtube.com/watch?v=wLAJ5sdtV6c

#3

Thanks Bob....you know we don't mess around.

I must have spent 30 minutes just staring at it and watching it 'print'...it's just that cool!

I must have spent 30 minutes just staring at it and watching it 'print'...it's just that cool!

#5

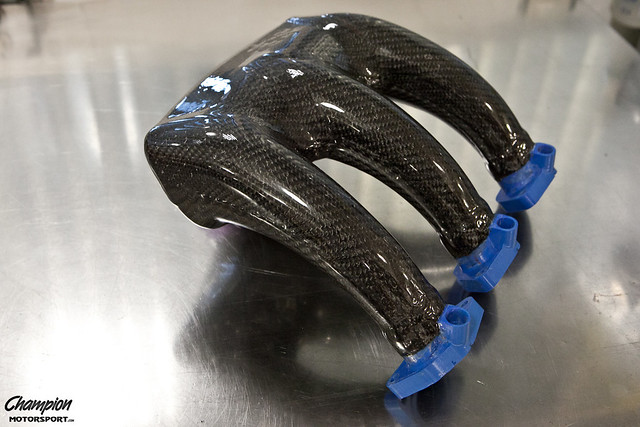

With the FDM we no longer have to use 2-piece molds because the carbon can be wrapped around the mold, rather then laid into the mold. It's mostly a benefit for parts that require a 360º wrap of carbon, or for parts with intricate designs, like our new carbon intake manifolds pictured below. The molds that the FDM produces are also essentially 'one time use' molds...a new one has to be printed for each part we make. For the splitters and diffusers we can just keep using the same mold over and over.

#7

Trending Topics

#8

The only real limit I can foresee at this time is the size of the mold you can produce (due to the size limitations of the machine itself).

The cool thing about this machine is that you don't necessarily have to print with a soluble material. You can also print with a plactic-like material that is actually about 5X as strong as ABS.

The cool thing about this machine is that you don't necessarily have to print with a soluble material. You can also print with a plactic-like material that is actually about 5X as strong as ABS.

Thread

Thread Starter

Forum

Replies

Last Post

arhim22

Automotive Parts & Accessories For Sale/Wanted

2

09-07-2015 08:49 PM